MIT Transportable Shielded Shelter (Catalog #03000-015)

The MIT Transportable Shielded Shelter is a satellite ground terminal housed in a shielded shelter. The shelter is a wheeled trailer constructed with the external appearance of a white commercial moving van. The internal configuration of the shelter is divided into an operations room, an equipment room, a cryptographic room, and generator bay, with a separate antenna trailer. The antenna trailer contains a GFE furnished antenna, raydome, and shielded equipment bay that is integrated on a trailer that can be towed separately. The shelter's roof, walls, doorways (when closed) and floor are electrically continuous to ensure continuous electrical bonding between structure members and all closed apertures. Design and fabrication methods are employed throughout the contract to maintain an excellent degree of shielding against the effects of electromagnetic pulses and to control RF emissions.

Shielded Trailer #1 (Catalog #03000-008)

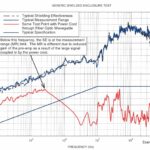

EMI built a 48-ft. EMI/RFI shielded trailer with air ride suspension to be used for remote operations. The trailer is a double drop design, with .050 riveted aluminum skin on the exterior and 10-gauge galvanealed steel with fully welded seams on the interior. The shelter is divided into four areas: shielded work space with workstations; shielded electronic equipment rack area; shielded vestibule; and an unshielded area housing power and data entry equipment. Interior finishes are carpeted or melamine walls and raised computer floors. Floor mounted unistrut channel is welded to the floor for equipment mounting. EMI provided and installed all wiring and lighting, cable raceways, ECU, personnel door platform/stair assembly, butcher block computer workstations, fax and printer racks, laminate fold-down work surfaces, and safety equipment. The trailers tested to –150dB typical shielding effectiveness. Under follow-on purchase orders, EMI provided nine more remote operations vans, essentially the same as the first, with the addition of a protected volume radio room in some units.

Shielded Trailer #2 (Catalog #03000-011)

This is a 48-ft. shielded shelter, constructed similarly to the Shielded Shelters previously built with variations in layout. As in the Shielded Shelters, this shelter provides a platform for electronic rack equipment and operator workstations. The shelter is divided into five areas on the main level: all shielded areas consisting of entrance vestibule in the rear, operator workstation area, equipment rack area, and storage area, with air conditioning units in the unshielded front area. The subfloor area houses an unshielded power area, a vestibule, a shielded volume with CORCOM filters, and provides storage for two detachable step assemblies. A protective volume serves as a transition area from dirty to clean areas via waveguide-beyond-cutoff penetrations. The contract required HEMP testing to MIL-STD-188-1256.

Shielded Trailer #3 (Catalog #03000-012)

This is a mobile power generation shelter, providing mechanical interface and structural support for generators, switchgear, electrical power distribution, lighting, and cable storage. This trailer is a shielded shelter, constructed similarly to the Shielded Shelters previously built, but with a different layout and purpose. It is divided into four main areas: unshielded radiator area in the rear containing engine radiators, fans, and spare tire winching capability; shielded generator room with two 100kw CFE generator sets, engine/generator controls, battery cabinet, automatic fire suppression system, and automatic oilier; unshielded forward storage area; and an exterior power distribution panel containing power connectors, shore power hookup, 24V connector, on-board selector switch, onboard power source circuit breakers, generator emergency stop, and fiber optic data connector. The contract required HEMP testing to MIL-STD-188-1256.

Shielded Trailer #4 (Catalog #03000-013)

This is a Mobile Power System consisting of two mobile power units (MPUs) which operate together, serving as a mobile power generation platform. The MPUs are shielded shelters, constructed similarly to the Shielded Shelters previously built, but with a different layout and purpose. The MPUs provide mechanical interface and structural support for generators, switchgear, electrical power distribution, lighting, cable storage and environmental control. The units are composed of six main areas; unshielded radiator area with auxiliary power unit, radiators and fans; shielded generator room with 350 KW generator sets and automatic fire suppression; shielded control room with switchgear; shielded vestibule; unshielded power entry and distribution area with power connectors, shore power, circuit breakers, APU control panel, power selector switch and ECUs; and a subfloor area housing Corcom filters, fuel tanks, oil reservoir, generator air filters, transfer pump, step assembly and cable storage. The contract required HEMP testing to MIL-STD-188-1256.

Shielded Trailer #5 (Catalog #03000-014)

This is a 53-ft. EMI/RFI shielded trailer with air ride suspension. The trailer is a double drop design, with .050-inch thick riveted aluminum skin on the exterior. On the interior 12-gauge galvannealed steel is installed on roof and floor, and 12-gauge galvanneal on the walls. All interior seams are fully welded. Foam-on insulation fills the wall cavities. The undercarriage is covered with a layer of foam-on insulation in the tunnel area and the SPV, followed by 3M undercoating for durability and rustproofing. All wiring and lighting, cable raceways, and environmental conditioning units are included. Rear personnel door is provided with platform and step assembly. The shelter is divided into several sections: The first section is a shielded vestibule that is the primary personnel egress/ingress for the shelter. The second section is the shielded workspace area that has space for 8 workstations. The third section is the shielded rack area accommodating space for equipment racks. The fourth section is the Special Protective Volume (SPV) for electronics and data entry equipment. The fifth section is the unshielded power area that contains the power entry equipment. The shelter provides environmental protection for personnel and electronic equipment during transportation, operations/deployment and storage according to customer specifications. On the interior, walls are finished with carpeting and the ceiling is covered with acoustical foam. Raised floors covered with 3/16 alum plating are provided. Unistrut channel is welded to the walls, floor and ceiling for equipment mounting and tiedown.